Engineering Custom Pelleting Line Designs

Bringing concepts to reality.

We have on-site engineers that work with our installation team to make sure there is little room for miscommunication and error. We custom design your system, implement the software and train your team to be self-sufficient. We set up a communication system for when the project is complete. We’re always just a phone call away!

Custom Designing Your Pelleting Line

Providing you with design concepts to improve production rates and your bottom line.

To start any project properly we need to determine your project goals, type of material you will be processing and the limitations of physical structures such as buildings, lot size, electrics, etc.

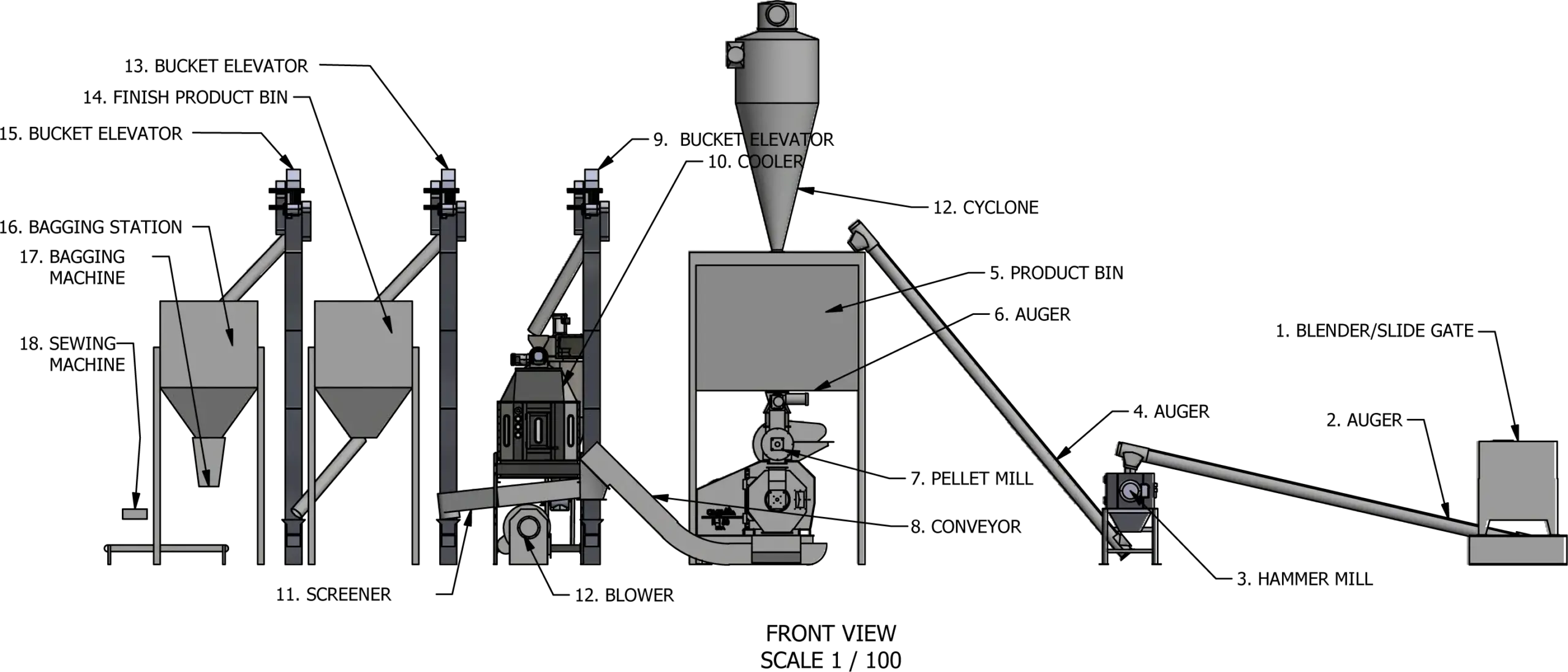

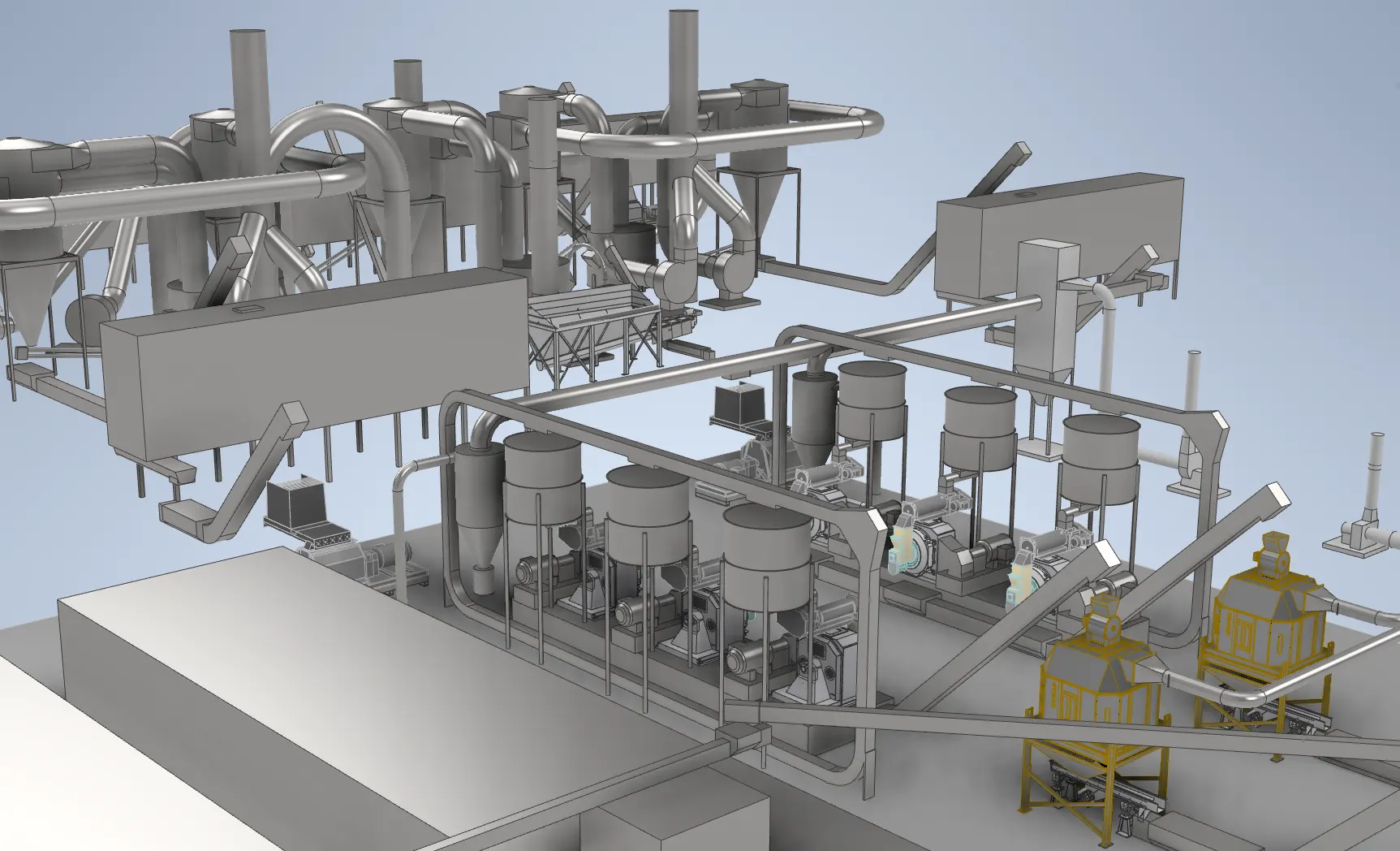

Once we have determined this information, we will be able to put together a rudimentary line process flow which we can use to provide you with a budgetary quote. If the budget quote is accepted, then we create a conceptual design CAD file. The concept CAD file is required to give you an accurate quote on the equipment required.

Meeting Your Needs, Creating A Plan

Our team will design, install, train and follow-up to make sure you have a seamless transition.

Our team really is a one-stop-shop. We will help you from product formulation, to sampling, to manufacturing the perfect pelleting line to create your pellet on-site and be in full production. If we don’t do it, we know the right person for the job.

Once you partner with CPS, know that your pelleting, manufacturing, bagging and logistics is taken care of. Now all that’s left for you to do is sell, sell, sell.

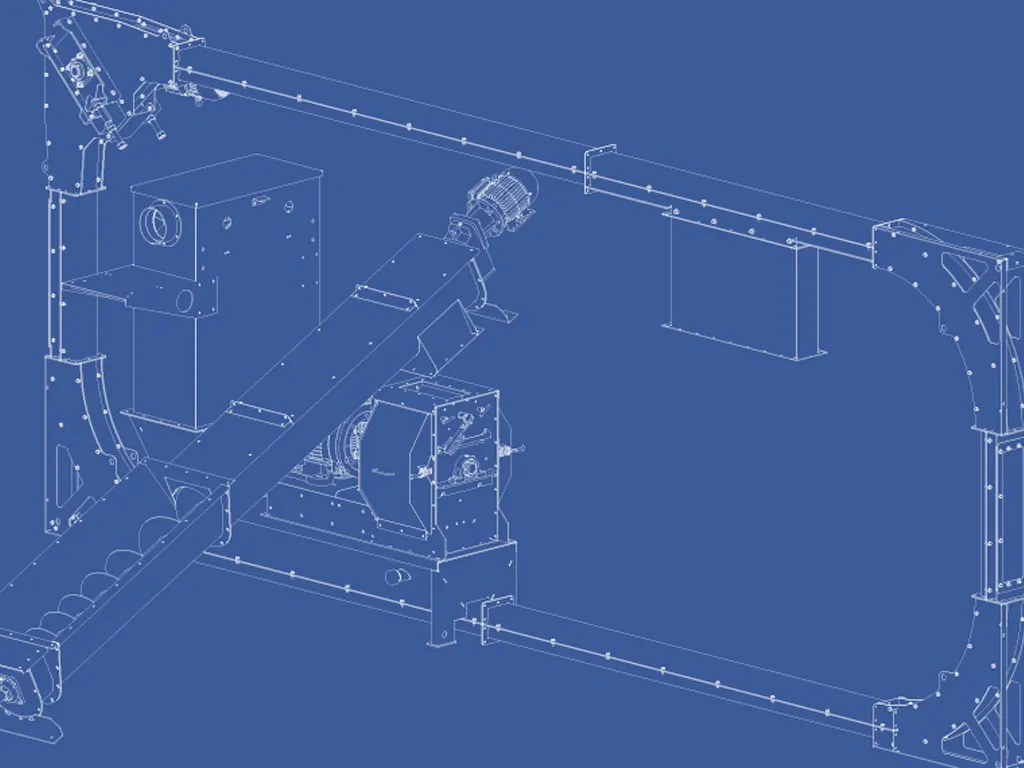

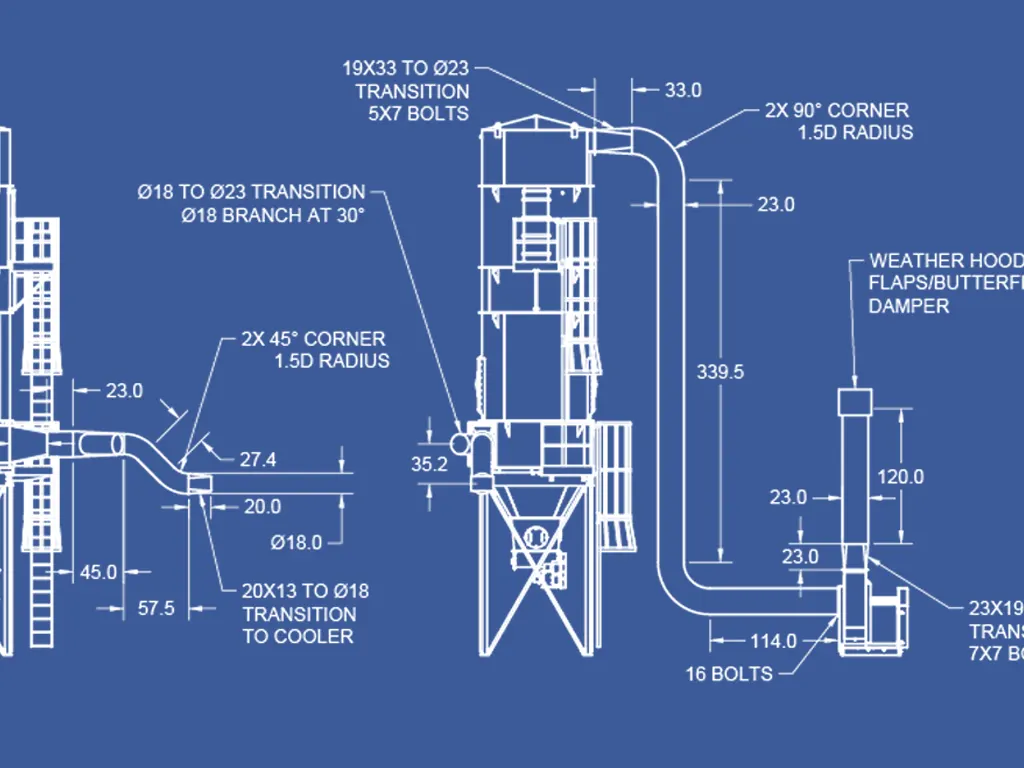

Detailed CAD Design

Get your questions answered and a plan in place with engineered CAD drawings.

The CAD files will include labeled equipment laid out in a 3D format, electrical requirements for the system and required building dimensions.

The CAD files can be used to:

- Determine equipment requirements

- Answer engineering questions

- Receive estimates on equipment needed

- Provide a visual tool for board members and investors to review

For more information about our Engineering & Design solutions, request a free consultation today!